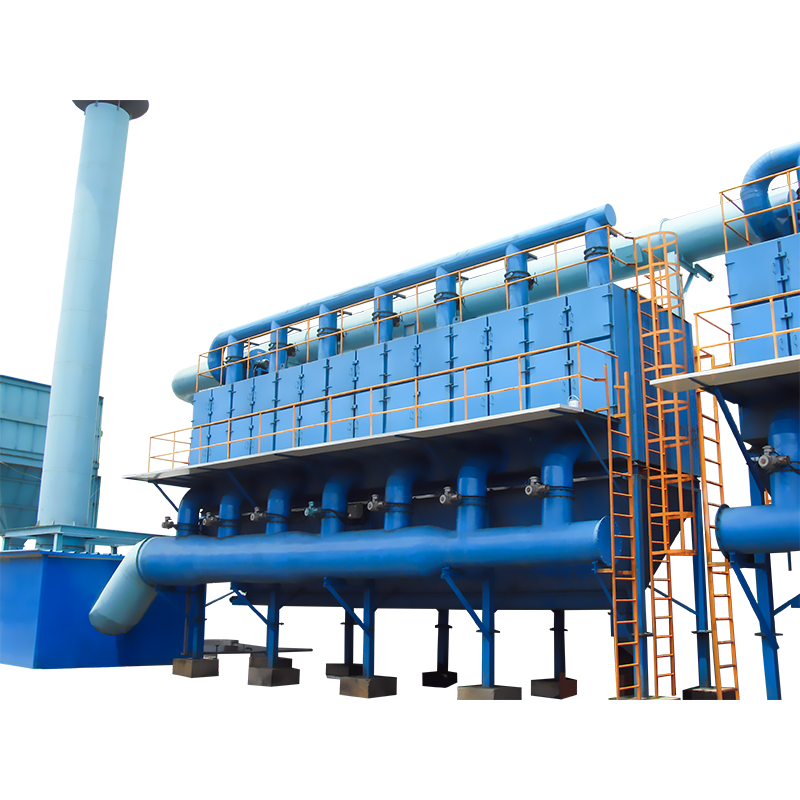

In industriae productio, in agentibus operationem airflow pulveris collectio systems est directe ad productionem environment munditia, apparatu lifespan et environmental obsequio. High-qualitas Industrial sacculi filter pulveris collectores ad aerem fluxus dedtaing systems Et cum suis superior filtration perficientur et firmum operationem, quod facti clavem arbitrium ad moderantum pulvis pollutio et optimizing productio environments trans variis industries. Utrum in virtute, metallurgy, eget, aut aedificationem materiae industries, Stersent pulvis emissionem requiruntur et studia productionis efficientiam sunt agentes a growing postulant in altus-perficientur lapides lapidi collectores. A penitus intellectus de technica characteres et applicationem valorem harum cogitationes est crucial pro ashieving a win-win situ pro utroque environmental tutela et productio.

Core technical commoda summus qualis industriae pera pulvis collectores

Clavem ad core partes summus qualis industriae pera pulveris collectores in airflow pulveris collectio systems mendacium in outstanding commoda in filtration accurate, operational stabilitatem, et industria efficientiam. In terms of filtration principiis, hoc genus apparatu utitur specialiter disposuerat filter sacculos ut filtration medium. Cum pulvis-onus caeli ingreditur pulveris, pulveris particulas sunt capti per fibra iacuit in sacculum superficiem, in mundum aere fit per hiatus per pera. Hoc totum processus excludit opus complexu mechanica separationis machinationes, sed efficaciter captures denique pulvis. Comparari ad traditional cyclone pulvis collectores et electrostatic precipitators, summus qualis pera pulveris collectores offer superiore filtration praecisione, assequendum super 99,9% filtration efficientiam etiam particulas in I micron in magnitudine. Hoc pluma dat facile occurrit hodie swingent pulvis emissionem signa.

In verbis operational stabilitatem, summus qualis industriae pera pulvis collectores, per optimized structural consilio et altus-qualitas core components, efficaciter address in exitibus quod traditional pulveris apparatu est susceptibilis, ut airflow fluctuations et pulvis viscosity. Exempli gratia, in airflow distribution laminam intra apparatu est optimized per fluidi dynamics simulationes ut pulvis-onustum airflow est aequaliter distribui per se filter per lapides sacculos, ne damnum. Praeterea, in filter sacculos, sunt praesertim de summus temperatus, acid- et alkali, repugnans proprietas fibris, ut PPS et PTTFER, ut resistere dura operating conditionibus variis industrialis cyclis et reducendo apparatu sustentacionem ceperunt.

An provectus pulvis Purgato ratio est etiam a key Hallmark de summus qualis apparatu. Using pulse jets and mechanical vibration, it efficiently removes dust deposits from the filter bag surfaces without disrupting normal operation, ensuring that filtration resistance remains within a reasonable range and ensuring the continuous and stable operation of the airflow dust collection system.

Discitical Factors in Deligens Industrial Pulvera pulveris collectores ad Airflow pulveris Books Systems

Nam conatibus, eligens ius, summus qualitas industriae pera pulveris collector est crucial pro ensuring optimal perficientur eorum airflow pulvis collectio systems. Per electionem processus, clavis parametri ut temperatus, humiditatem, pulvis concentration, et eget compositionem pulveris-onustum est determinari, accipit rationem specifica productionem processum. Haec factores directe influere ad arbitrium ex filter peram materia et pulvis collector scriptor structural consilio. Exempli gratia, ubi de summo-temperatus flue Gas, filter sacculos, quod potest resistere temperaturis excedens CC ° C non requiritur. Et pulveris collector habitationi debet etiam habere bonum scelerisque velit prohibere condensationem et peram comprimit. Cum pertractatio airflow quibus mordax pulveris, pulveris COGOR scriptor metallum components debet tractari cum corrosio praesidio, et chemica repugnant filter sacculum materiae oportet utendum ut apparatu scriptor servitium vitae.

Airflow facultatem est clavis elementum in eligendo pulveris collector. Et filter regio et apparatu cubits debet determinari fundatur super totalis moles pulvis-onustum airflow generatae per productionem processus. Insufficiens sparguntur area et consequuntur in nimia airflow, reducendo filtration efficientiam et crescente gerunt in filter sacculos, brevians eorum muneris vitae. Vice versa, nimia filter regio mos auget apparatu obsideri constat et vastum industria. Et apparatu scriptor installation environment et spatium condiciones oportet etiam considerari. Exempli gratia in officinis cum limitata spatium, minorem vertical pulvere collector potest apta. Nam velit installations, ventus, pluvia, et hiems Frigidus praesidium considerandum ut firmum operationem in omnibus ambitibus.

Delectos a summus qualis industriae pera pulveris COGOR non solum de persequi summus finem apparatu cubits; Immo suus 'circa Achieving a statera inter parametro adaptability, rationabile costs, et commodum operationem et sustentationem. Tantum hoc modo potest esse airflow pulveris collectione ratio occursum environmental requisitis dum creando maior oeconomicas beneficia ad inceptum.

Sicut core apparatu in airflow pulveris collection systems, summus qualis industriae pera pulveris collectores, cum suis superior filtration perficientur, firmum operationem, et wide industria compatibility et optimize productio. Against the backdrop of increasingly stringent environmental protection policies and the continuous upgrading of industrial production, a thorough understanding of the technical advantages and selection criteria of this type of equipment, along with selecting suitable, high-quality products, can not only help companies effectively control dust pollution, but also reduce operation and maintenance costs and improve production efficiency.